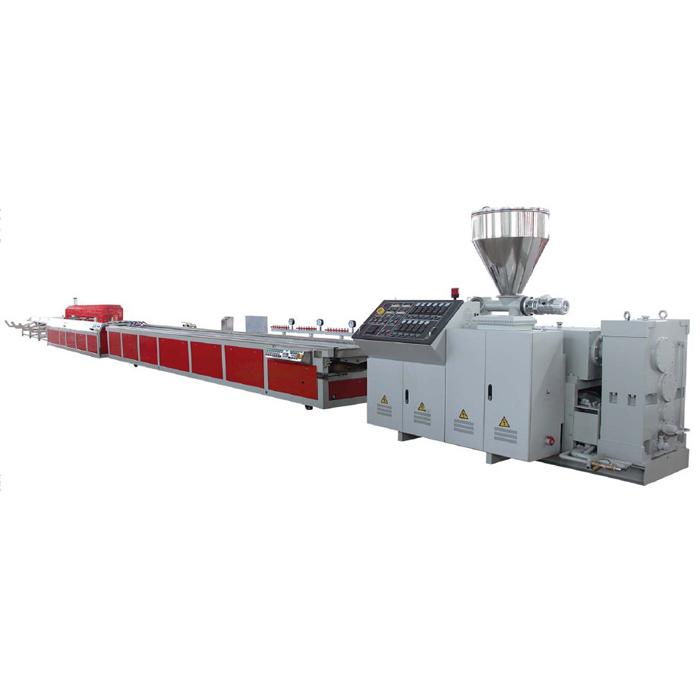

Introduction to the characteristics of the wall panel production line and the scope of application

High-density polyethylene and modified carbon are selected as the main raw materials for the production of the wall panel production line, and a new type of power cable protection pipe produced by the wall panel production line with rotational molding technology. With its excellent performance, it is currently an ideal buried cable protective casing material in the construction and transformation of urban street lamp underground engineering, electrical and chemical engineering, cable communication, high-speed power and other projects in my country.

Product features of the wall panel production line:1. The wall panel production line has good toughness, can be cut according to the needs of use, can reach obstacles, and is convenient for construction and maintenance.2. The wall panel production line is light in weight and easy to handle.3. The wall panel production line has high strength and high compressive strength of the threaded shape, even if it is buried deep underground, it will not be deformed under high pressure.4. Excellent corrosion resistance, it can still ensure normal operation under harsh conditions such as acid, alkali and salt, and has a long service life.5. Safe to use.6. The wall panel production line has smooth appearance, low friction coefficient, no wire lead in the pipe, and convenient threading.7. The wall panel production line has low cost, low construction cost, fast construction and short construction period, which has high economic benefits.