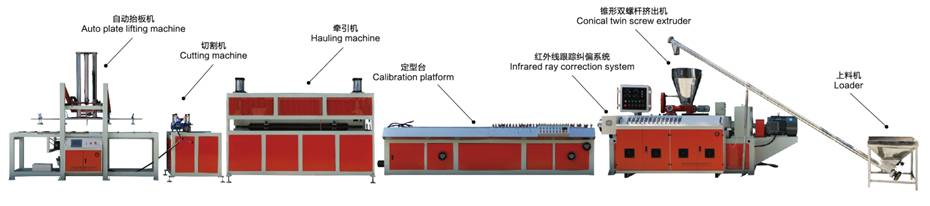

PVC Ceiling Integrated ceiling gusset production line

PVC integrated ceiling gusset plate production equipment: mainly spring feeder (supported by the host), SJSZ65/132 conical twin-screw extruder, gusset die, vacuum setting table, gusset heat transfer machine, rubber block tractor, cutting Machine, stacking rack. Auxiliary machine part: high mixing unit, crusher, mill (efficient production and recycling)

- Shipping:

Learn More

Features of PVC Ceiling Integrated ceiling gusset production line: PVC gusset production line is mainly used for the extrusion of PVC door and window profiles, wide door panels, window sills, and porous threading pipes (four holes, six holes, seven holes, nine holes, etc.). The production line can choose different specifications conical twin-screw extruders according to different profile sections and molds, and configure the corresponding vacuum setting table, tractor, cutting machine, turning platform and other auxiliary equipment.

The extrusion capacity of the host can be between 60 kg and 300 kg per hour.

The tractor adopts our company's unique lifting technology, which has stable operation, good reliability and great traction. Vacuum shaping adopts a special enlarged vortex cooling system, which is convenient for cooling and shaping to meet the needs of high-speed extrusion.

The moving speed of the cutting machine is synchronized with the traction speed. All actions are controlled by imported PLC computer. The design is reasonable, the operation is stable, and it can automatically cut to a fixed length, and is equipped with a dust recovery device.

Main technical parameter

| Extruder | SJZ55/110 | SJZ65/132 | - | SJZ80/156 | - | SJZ92/188 |

| Mail Power(kw) | 22 | 37 | - | 55 | - | 110 |

| Product Width(mm) | Max240 | Max240 | Max300 | Max600 | Max900 | Max1200 |

| Vacuum Pump Power(kw) | 2x5.5 | 4x5.5 | 4x5.5 | 4x5.5 | 1x7.5 2x11 | 2x7.5 2x11 |

| Water Pump Power(kw) | 1.5 | 4 | 4 | 7.5 | 7.5 | 7.5 |

| Haul Off Speed | 0-5 | 0-5 | 0-5 | 0-3 | 0-2.5 | 0-5 |

| OutPut(kg/h) | 100 | 220 | 220 | 350 | 350 | 750 |