PVC/PE High Speed Turbine Plastic Pulverizer

This PVC plastic mill is mainly used for grinding PVC. The gap between the fixed knife and the movable knife can be adjusted, so you can use a mill to obtain different sizes of PVC powder.

- Shipping:

Learn More

The characteristics of the developed new milling machine are as follows:

(1) Compared with similar mills, the output is greatly improved (20%-50% increase in output) under the same power condition, and energy consumption is saved.

(2) A dust collector is added, which effectively reduces dust pollution.

(3) The discharge of the main fan reduces the labor intensity of the operators.

(4) The door cover of the main machine can be opened, which is convenient for maintenance and tool replacement.

(5) The use of wind and water double cooling can better reduce the working temperature in the machine body, and the materials developed are not easy to change. At the same time, it is also conducive to the grinding of heat-sensitive plastics. Part of PE and ABS can be ground.

working principle

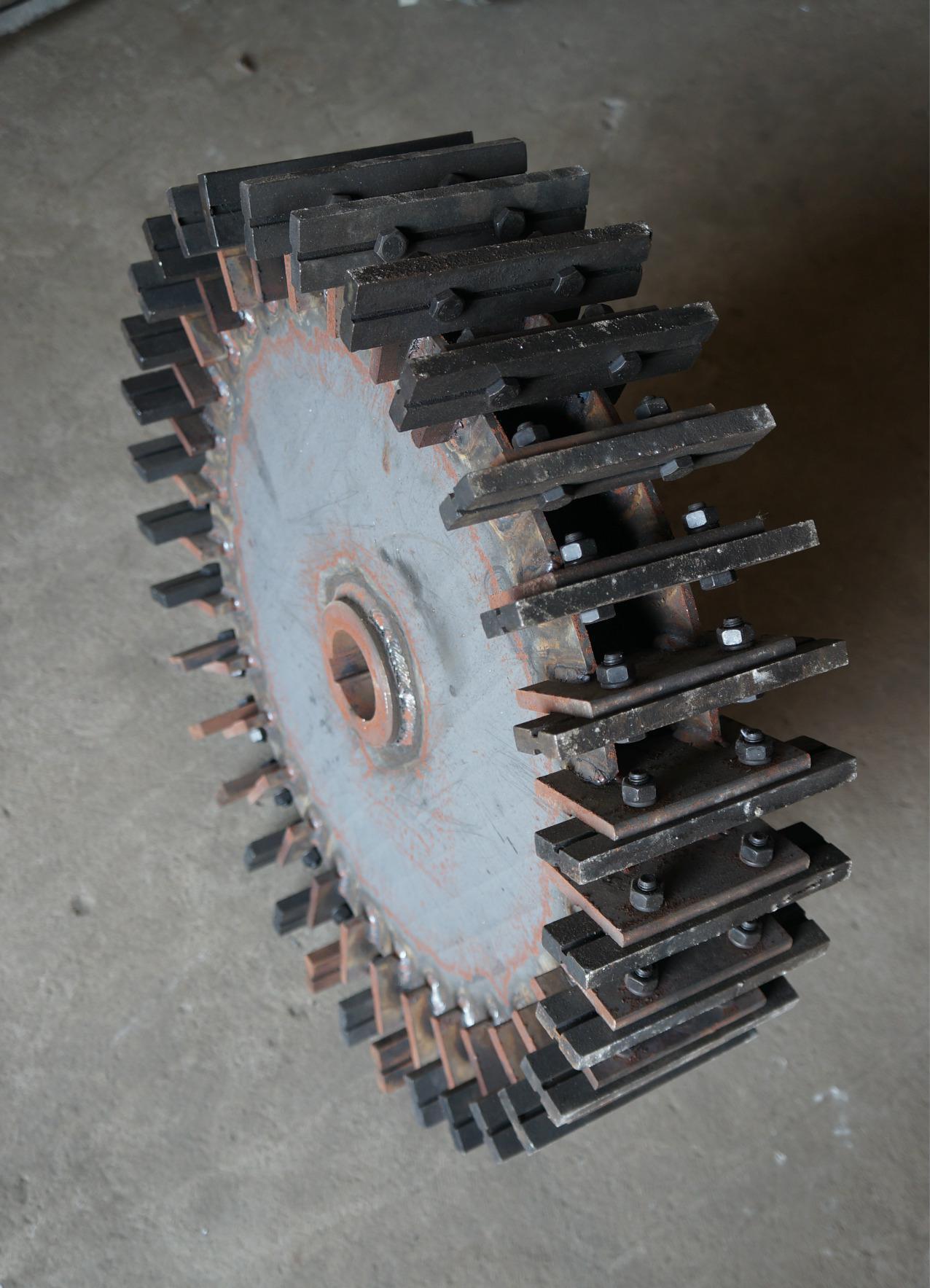

· The working part of the machine is a cutter head. The high-speed particles are partially crushed after impacting the tooth plate and drawn out by suction, while the larger particles continue to impact and are drawn out after crushing. This reduces the load on the cutter head, improves the grinding efficiency, and enables the powder to be evenly cooled.

· Low temperature is the main advantage of this machine. In terms of thermal power equivalent: it is converted into 860 kcal of heat per hour after the work is done. This machine is external ventilation. The air volume reaches 50m/KW, and most of the heat is taken away by the temperature difference between the inlet and outlet air. A small part of the heat is solved by water cooling. The inlet temperature of the cold water is required to be no more than 25°C, and the outlet water temperature is no more than 45°C. In summer, the cooling water flow should be appropriately increased to lower the temperature.

Model | SMW400 | SMW500 | SMW600 | SMW800 |

| Diameter of Grinding Disc (mm) | 390±1 | 483±1 | 583±1 | 783±1 |

| Rotary knife (pcs) | 60 | 24 | 28 | 36 |

| Fixed knife(pcs) | 6 | 12 | 14 | 6 |

| Motor Power(kw) | 30 | 37 | 45 | 75 |

| Weight(kg) | 1580 | 2280 | 2680 | 3280 |

| Machine Size(mm) | 2200*1500*1600 | 5600*1500*2900 | 5900*1600*3200 | 6200*2200*4200 |

| Output(kg/h) | 50-120 | 100-260 | 160-450 | 250-850 |